Why Supplier Consolidation Is the Key to Procurement Efficiency

For many manufacturers, managing a large supplier base feels like a sign of strength. More suppliers mean more options—at least in theory. But in practice, the opposite is often true. Companies juggling hundreds of small, low-volume suppliers face higher administrative costs, fragmented communication, inconsistent quality, and little visibility into true spending patterns. What looks like flexibility actually becomes a costly operational burden.

This challenge becomes even more significant when dealing with C-article procurement and indirect suppliers that contribute only marginally to purchasing volume, yet consume a disproportionate amount of time and resources. In many cases, the administrative work required to manage these suppliers exceeds the value of the goods purchased from them.

Building on the principles explored in our previous article about the Pareto principle in supplier management, the reality is clear: the top 20% of suppliers often generate 80% of your purchasing value, while the remaining 80% generate only 20%—yet account for the majority of administrative workload. This imbalance is one of the strongest arguments for supplier consolidation as a core procurement strategy.

Why Too Many Suppliers Hurt Procurement Performance

The more suppliers a company manages, the more complex its operations become. Every supplier—regardless of order size—requires contract negotiations, quality checks, logistics coordination, order tracking, invoice processing, and ongoing communication. When these suppliers are spread across countries such as China, India, Vietnam, Thailand, and Mexico, the burden increases even further.

Supplier fragmentation typically leads to:

-

Higher internal administrative costs

-

Increased risk of delays or miscommunication

-

Limited negotiation power due to low-volume orders

-

Inconsistent quality and unreliable lead times

-

Too many uncoordinated shipments and higher freight costs

Even well-structured procurement teams struggle to manage these inefficiencies over time. Consolidation becomes not only strategic, but necessary.

How Supplier Consolidation Improves Efficiency

Supplier consolidation allows companies to streamline operations by working with fewer, more capable, and consistently vetted suppliers. It also enables stronger partnerships, clearer communication, and higher negotiating leverage.

When companies consolidate suppliers—especially for lower-volume or low-value items—they experience measurable improvements such as:

Reduced Administrative Burden

The cost of managing a single supplier often ranges from €500 to €1,500 per year. Consolidating dozens or hundreds of small suppliers into one managed source immediately reduces internal workload and frees up procurement teams to focus on strategic activities.

Better Pricing Through Volume Aggregation

Larger, consolidated orders allow suppliers to optimize production and offer better pricing. Companies also gain leverage to negotiate terms and secure longer-term pricing stability.

Improved Quality and Operational Consistency

Working with fewer, well-monitored suppliers reduces variability. Quality processes become standardized, communication is clearer, and the risk of misalignment drops significantly.

Simplified Logistics and Fewer Shipments

A consolidated supply base reduces the number of purchase orders, shipments, customs entries, and warehouse receiving operations—leading to direct cost savings and smoother overall operations.

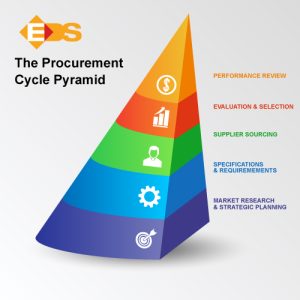

How EDS Helps Companies Consolidate and Manage Suppliers

EDS International specializes in helping manufacturers transform chaotic, fragmented supplier networks into efficient and scalable sourcing structures. With teams on the ground in India, Vietnam, Thailand, China, and Mexico, we directly manage suppliers, coordinate production, conduct quality inspections, and consolidate orders to simplify your procurement.

Our services include:

-

Identifying and replacing low-performance or small-volume suppliers

-

Managing all indirect or C-article suppliers under one roof

-

Providing a single point of contact for all sourcing activities

-

Performing full supplier vetting, auditing, and quality inspections

-

Optimizing shipment consolidation to reduce freight costs

By acting as an extension of your procurement team, EDS ensures efficiency, transparency, and cost savings across the entire sourcing cycle.

Why Supplier Consolidation Matters More Than Ever

As global supply chains continue to evolve, companies must prioritize agility, resilience, and cost control. Excess supplier networks are no longer sustainable. Consolidation allows manufacturers to gain clarity, reduce risk, and secure long-term operational stability—without sacrificing quality or flexibility.

If you want to optimize your sourcing strategy, reduce complexity, and improve procurement performance, supplier consolidation is one of the most effective levers to pull.

And EDS International is the ideal partner to help you get there.

With nearly 40 years of experience, a global presence, and proven supplier management capabilities, we help companies streamline their supplier base while ensuring cost savings, transparent operations, and high-quality manufacturing.