Hidden Inefficiencies in Your Procurement Process — and How to Fix Them

Even the strongest procurement teams face performance leaks that quietly drain time, money, and resources. These inefficiencies often go unnoticed because they occur across multiple touchpoints — during supplier communication, quality inspections, order coordination, logistics, and even internal workflow management. Over time, they increase total cost of ownership and weaken a company’s ability to scale effectively.

The most impactful improvements rarely come from negotiating prices harder. They come from optimizing the processes that surround sourcing. At EDS International, we regularly audit procurement operations for manufacturers in the U.S. and Europe, identifying hidden gaps and implementing structured solutions that deliver measurable savings.

Uncoordinated Orders and Fragmented Purchasing Decisions

One of the most common inefficiencies arises from departments placing orders independently. When each team communicates separately with overseas suppliers, companies lose volume leverage, face inconsistent lead times, and struggle with unnecessary administrative work. The result is higher unit costs and a lack of transparency on the true annual spend.

Centralizing communication and consolidating orders not only reduces administrative burden but also enables strategic purchasing. When EDS manages supplier relationships, all communication flows through a coordinated channel, giving companies visibility into pricing, MOQs, production timelines, and supplier performance across the full product range.

Inconsistent or Late Quality Checks

Quality issues rarely begin at the end of the process, yet many companies rely on final inspections only. This leads to higher reject rates, rework, delays, and emergency shipments — all of which dramatically inflate costs. Local quality teams are essential for catching issues before production finishes, ensuring that problems are corrected in real time.

EDS places engineering and QC teams inside suppliers’ countries — including China, India, Vietnam, Thailand, and Mexico — to inspect materials, monitor production, confirm compliance, and validate shipments before they leave the factory. This proactive approach minimizes disruptions and helps clients avoid expensive surprises.

Unmanaged or Incorrectly Estimated Freight Costs

Freight is often treated as a downstream detail, but it can account for a significant share of total landed cost. Inefficiencies arise when shipments are sent half-full, routed through costlier carriers, or consolidated poorly. Companies also lose value when they fail to optimize container utilization or choose the wrong Incoterms for their situation.

By monitoring production schedules and coordinating logistics across suppliers, EDS ensures consolidations happen efficiently, containers ship at optimal capacity, and freight decisions reflect real-time market conditions. This logistical discipline reduces both shipping costs and transit risks while supporting continuous supply.

Lack of Supplier Performance Tracking

Many procurement teams work with suppliers for years without formal scorecards or structured evaluations. This makes it difficult to identify reliability problems, quality trends, or emerging risks. Without data-driven visibility, companies remain reactive rather than strategic.

At EDS, supplier vetting includes detailed assessments of quality, delivery performance, communication, capacity, financial health, and compliance. These evaluations continue throughout the relationship, ensuring that only high-performing suppliers remain in the network and that performance issues are addressed immediately.

How EDS Eliminates These Inefficiencies

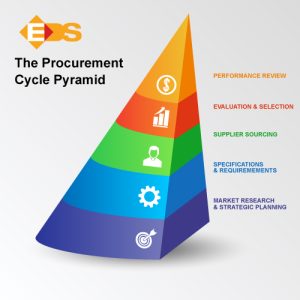

A procurement process becomes efficient when every stage works in harmony — sourcing, communication, auditing, production oversight, logistics, and post-shipment evaluation. EDS delivers this by acting as an extension of your team on the ground, coordinating every step and ensuring no detail is overlooked.

Our approach includes:

-

Comprehensive supplier audits

-

Centralized communication and order coordination

-

Local engineering and QC teams

-

Strategic freight optimization

-

Real-time supplier performance tracking

This end-to-end model strengthens control, reduces waste, and increases the value procurement creates across the organization.

Why EDS International Is Your Best Partner for Procurement Optimization

For over 40 years, EDS has helped manufacturers eliminate hidden inefficiencies, reduce total cost of ownership, and build stronger supplier relationships. With our local offices, engineering teams, and quality specialists, we ensure every component — from sourcing to delivery — is managed with discipline, transparency, and measurable results.

If you want to improve procurement performance while controlling cost, EDS International is the partner that makes it possible.

👉 Contact us today to begin optimizing your supply chain.