Solving C-Article Sourcing Pain: How EDS Can Be Your Single Source Manager

Addressing the Hidden Costs and Headaches of C-Article Procurement

In many manufacturing and industrial operations, the procurement focus naturally gravitates toward major components, systems, and high-value parts. Yet C-Article—those small, consumable, indirect materials like fasteners, fittings, clips, and maintenance supplies—can quietly consume disproportionate time, budget, and operational risk.

Many companies struggle with fragmentation: hundreds of suppliers, inconsistent quality, fragmented ordering processes, high stockouts, and excessive administrative overhead. Often, procurement teams spend more time chasing small orders, reconciling invoices, and coordinating logistics than focusing on strategic sourcing efforts.

These pain points are real:

-

Procurement fragmentation causes inefficiencies in purchasing, receiving, invoicing, and quality control.

-

Supplier diversity means dozens of relationships to manage, with little leverage or consistency across orders.

-

Quality variation and warranties: when many suppliers are chosen on short notice, product defects and compatibility issues can rise.

-

Logistics and minimum order constraints drive up cost per piece or create delivery delays.

-

Administrative burden: creating POs, reconciling small-dollar invoices, and resolving mismatches consume resources out of scale.

The challenge isn’t glamorous, but the impact is heavy: hidden costs, inefficiencies, and supply risk.

How EDS Becomes Your Single-Source C-Article Partner

What if instead of dozens of C-article vendors, you had one partner managing them all—end to end—with accountability and visibility? That’s precisely how EDS positions itself for clients who want to offload the complexity.

Consolidated Procurement & Volume Leverage

By aggregating volume across multiple clients and categories, EDS secures better pricing and terms for consumables and indirect parts than any one buyer could alone. You benefit from lower landed cost and stronger negotiating power.

Supplier Rationalization & Vetting

Instead of onboarding new, unknown suppliers, EDS maintains a vetted network of reliable manufacturers. Through our supplier audit and vetting services, we select C-article vendors with consistent quality, ethical compliance, and reliable capacity. This ties back to our broader sourcing methodology.

Quality Control & Spare Parts Consistency

When EDS manages your C-article, we ensure standardization—so spare parts remain compatible, replacements meet specifications, and warranty issues are reduced. We oversee inspection, testing, and ongoing quality metrics.

Logistics & Inventory Support

We coordinate ordering, warehousing, replenishment, and JIT distribution to plants. That means less administrative overhead for you—and fewer stockouts or overstock situations. With EDS managing lead times and buffer stock, your operations stay lean and reliable.

Single Point of Accountability & Transparency

You get one dashboard, one supplier, one performance contract. EDS becomes the accountable partner for all indirect material sourcing—meaning fewer headaches, better metrics, and a more strategic procurement function.

📘 Read our case study “How EDS International Helped an Industrial Manufacturer Optimize Global Supply Chain Operations and Reduce Costs”

Transitioning to Single-Partner C-Part Management

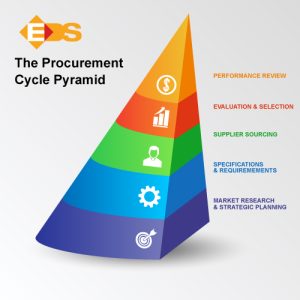

Switching to a model where EDS manages your C-article isn’t instantaneous. Key steps include:

-

Auditing your current supplier base and consumption patterns.

-

Rationalizing overlapping SKUs and consolidating supplier relationships.

-

Migrating orders and contracts under EDS oversight gradually.

-

Monitoring service-level agreements, quality KPIs, and cost trends.

-

Iterative optimization of vendor mix and logistics design.

Over time, the complexity fades and governance becomes simpler. You regain procurement capacity to focus on core components and innovation.

Why EDS Is the Ideal C-Part Partner for You

EDS International brings decades of sourcing expertise, deep global networks, and the operational rigor required to manage the “messy middle” of procurement. We offer:

-

Full end-to-end services including supplier vetting, offer negotiation, logistics, inspections, and quality control

-

Integrated supplier management and reporting capabilities

-

Scalability across regions such as India, Vietnam, Mexico, and more

-

A track record of improving cost, lowering risk, and reducing procurement burden for clients

If your procurement team is struggling under the load of C-article, or beginning to lose control over spend, EDS is your best partner to consolidate, optimize, and take control of indirect materials sourcing.

Contact us to explore making EDS your single-source partner for all those “small but costly” parts.