When to Outsource Supplier Management — and When to Keep It In-House

As supply chains become increasingly global and complex, managing suppliers effectively has become a strategic priority. Yet many manufacturers still struggle to determine the right balance between internal control and external support. Should supplier relationships be handled entirely by in-house procurement teams? Or is it more efficient to outsource supplier management to an experienced sourcing partner?

The answer often depends on your company’s scale, product portfolio, internal resources, and long-term goals. Managing overseas suppliers — especially across China, India, Vietnam, Thailand, and Mexico — can require daily coordination, on-site validation, engineering knowledge, and cultural fluency. When these capabilities are missing or stretched thin, costs rise and risks increase.

This article explores the advantages and limitations of both models to help you determine which approach brings more value to your business.

When Keeping Supplier Management In-House Makes Sense

Internal supplier management works well when companies have strong procurement systems, dedicated teams, and a relatively small, stable supplier base. Companies that produce in large volumes with long-term, high-value suppliers often benefit from keeping these strategic relationships internal.

In these cases, in-house teams maintain full control of negotiations, planning, and long-term collaboration. When suppliers are located locally or when products involve sensitive IP or proprietary processes, internal management can strengthen alignment and consistency.

However, internal teams tend to face challenges when suppliers are spread across multiple countries, time zones, or languages—or when purchase volumes are unpredictable. Without local presence or engineering expertise, companies may miss early warning signs of quality issues, delays, or compliance problems.

When Outsourcing Supplier Management Delivers Better Results

Outsourcing supplier management to a specialized sourcing firm brings significant advantages when companies buy from multiple low-volume suppliers, enter new sourcing regions, or struggle with communication and oversight.

A partner like EDS International provides a complete support system that most manufacturers cannot build internally:

engineers on the ground, inspectors inside the factory, culturally fluent staff, and long-standing supplier relationships in key sourcing markets. This eliminates barriers such as communication gaps, limited quality control, and lengthy problem resolution cycles.

Outsourcing becomes especially valuable when expanding into new countries. Instead of spending months vetting suppliers, negotiating terms, and navigating cultural nuances, companies gain immediate access to trusted networks and proven processes.

Key Indicators That It’s Time to Outsource

Manufacturers often turn to EDS after recognizing recurring issues such as:

-

Frequent quality problems or inconsistent product specifications

-

Overloaded procurement teams unable to manage daily supplier communication

-

Unpredictable lead times, shipment delays, or lack of production visibility

-

High administrative workload from managing many small or low-volume suppliers

-

Difficulty evaluating suppliers due to lack of local presence or engineering expertise

-

Rising total cost of ownership due to rework, returns, or emergency shipments

These challenges signal that in-house processes are no longer sufficient — and that a more structured, locally supported approach is needed.

A Hybrid Model: Keeping Control While Outsourcing Complexity

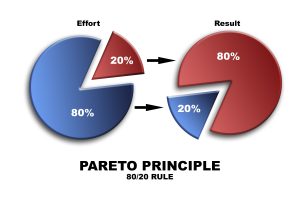

For many companies, the best solution is not fully internal or fully outsourced, but a hybrid model. Strategic procurement decisions stay in-house, while operational work — sourcing, vetting, inspections, communication, and logistics coordination — is handled by a partner with proven regional expertise.

This approach preserves control while improving execution, speeding up projects, and reducing risk.

EDS often acts as an extension of clients’ procurement teams, managing the day-to-day complexities while ensuring alignment with internal priorities. This gives companies the visibility they need with none of the burden of managing overseas suppliers directly.

Why EDS Offers Better ROI Than Managing Everything In-House

Building an internal global sourcing structure requires hiring local teams, training engineers, contracting inspectors, establishing networks, and maintaining multilingual communication. This is expensive and time-consuming.

EDS delivers all of this instantly — at a fraction of the cost.

With offices and teams across India, Vietnam, Thailand, China, Mexico, Colombia, and the U.S., EDS provides end-to-end supplier management, including:

-

Supplier identification and vetting

-

Engineering and quality inspections

-

Production monitoring

-

Price benchmarking and negotiation support

-

Logistics coordination

-

Risk management and supplier audits

Clients benefit from faster execution, lower risk, and more consistent quality — without expanding internal headcount.

EDS International: Your Partner for High-Performance Supplier Management

Whether you want to expand into new sourcing regions, reduce risk, or lighten your procurement workload, EDS International offers the expertise, local presence, and operational discipline needed to manage suppliers effectively. For over 40 years, we have helped manufacturers in Europe and North America build reliable, competitive, and cost-efficient global supply chains.

If you’re evaluating when to outsource supplier management, EDS is the partner that delivers clarity, efficiency, and measurable value at every step.

👉 Contact us today to strengthen your global supplier strategy.